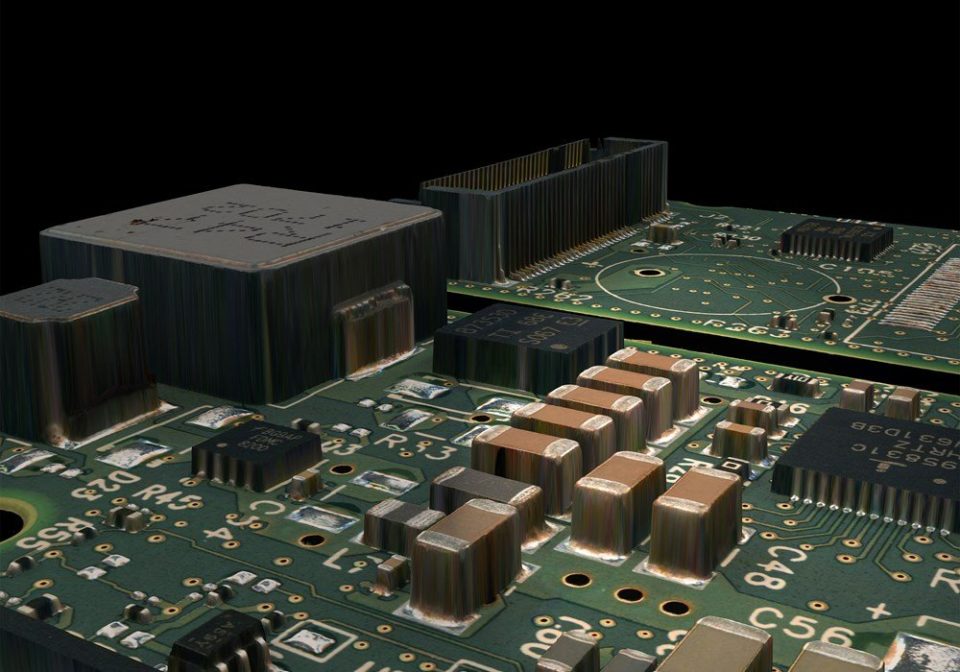

To find out defects, automatic optical inspection systems used different visual methods, which enable them to monitor printed circuit boards defect. The automated optical inspection system in Malaysia works its best. Hence, it will allow themselves to detect different kinds of surface featured effects like scratches, nodules or stains and dimensional defects like shorts open circuits for thinning of the solder. Besides this, these automatic optical inspection basics also can detect missing components, faulty components or incorrectly placed components. Previously these defects have been seen by Bhai Main dual operators, which are not up to the mark, and now with the help of AOI, these defects can be detected more accurately and swiftly.

High definition camera can be used to scan the boat’s surface visually, and thus they will be able to detect the defects present in the fabric or board. Using this high-quality camera, an automated optical inspection machine will be a capable build-up of a board picture. Dust captures the image that is processed and then compares it with the desired one to find any defect that may occur. With the help of this comparison, the automatic optical inspection system will highlight and detect any defects in the areas. By using a wide variety of techniques, the AOI will analyse whether a board is satisfactory or not.

Pattern matching

By using the technique of pattern machine, the automatic optical inspection system will be able to store various information related to good and lousy PCB assemblies and match it with the obtained image to find out any defect that may occur.

Template matching

This technique can be used in an automatic optical inspection system to compare the image obtained by high definition camera with the image from a golden board. This defect component inspection Malaysia plays a vital role in protecting any of the floors present in the manufacturing unit and help the manufacturer take the necessary action to save a lot of costs.

Statistical pattern matching

As the name suggests, this technique of automatic optical inspection system is similar to pattern matching. Still, it uses a statistically-based method to address the problem of Defence. Due to the presence of different boards and types of failure, it can also detect minor acceptable deviation.

With the advancement and improvement of Technology, the AOI system can accurately predict the defects which may occur in the manufacturing system hand. There is very much less chance that this system will find no flaws. To open the right manufacturing objective, please automatic optic pension system play a vital role in providing a sophisticated manufacturing environment to the manufacturers by producing less defective products.